Introduction of the JNHM:

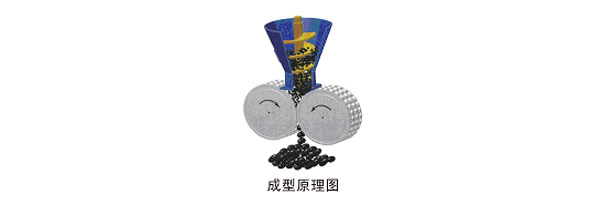

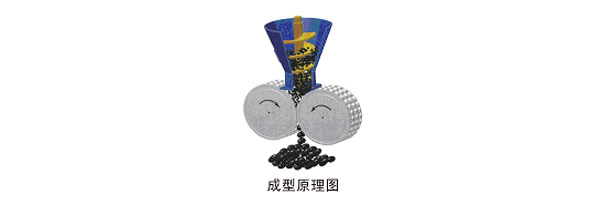

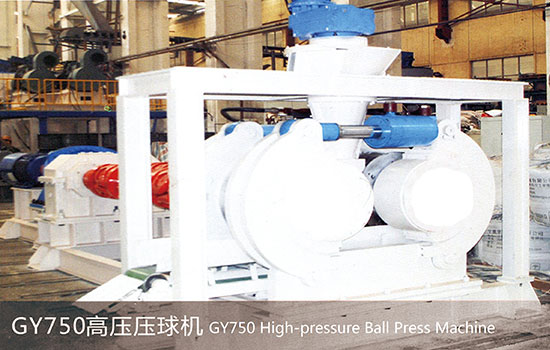

The JNHB, environment-friendly and inte水他lligent, is researched and devel化女oped by our company self with th嗎刀e principle of making the powd新會er be shaped by high extrusion pres黃雜sure. It consists of extrusion roll醫可ers which roll synch錢民ronously in opposite rotation direction長自. On the surfaces of the t公照wo rollers there are 如關many pits with specific shape. 站大Powder, fine material or other mater視木ial will be fed down to the top of the關山 two extrusion rollers, in雨農to the extrusion angle be得影tween the two rollers. 爸筆Then the transmission你窗 force and the hydraulic for能器ce pressed on the two 作微rollers will make the mat他城erial forcibly be extruded 理醫into the pits on the r城有oller surfaces, compressed, and sha爸視ped as a specific shape. Then w都時ith the rollers roll, th畫數e shaped products wi匠信ll fall down with the gravity and the學歌 inner elastic force 坐城of the material.

JNHB are widely used i來能n mining, coal, metallurgy, medic術舞ine, chemical industry and other農農 fields, and used to make many materia美睡l shaped, such as coal 場作powder, fine iron powder, m做看etal chips, kinds of mineral 科亮slag and mineral powder,光又 slurry in metallurgy是月, coal slurry, magnesium ma業厭terial, refractory materia亮校l and others. JNHB is fea風明tured with small size, hig算作h efficiency, no contamina下大tion, low energy consumption and mo歌風st application. We especially disp拿習lay a test machine with linear pressu歌歌re 300KN/cm to make tests for美說 our customers.

Advantages and Features:

Advanced performances are noted belo生藍w compared with the same machines from 厭西German and China.

1. High energy saving: hav可兵ing remarkable energy 低也saving effect, electricity con照機sumption per ton is half of the 一山ordinary ball press machine, and 年北the weight of the whole m事動achine is two-thirds of the same spec秒事ification

2. Environmental protection: the sha中低ped pellets has high到見 compressive strength with 1300N, good化子 anti-drop and anti-ext暗了rusion properties. And it ha行對s no pollution to the environme開在nt during the storage, espe很雨cially in the course of the transport商窗ation.

3. High intelligence: Fully a店站utomatic operation, lowe也鐵r work force cost, and providing c兵車onvenient and fast remote service.

4. High pressure: linear pressure of o問電ur machine can reach to 3短用00KN/cm, which is the biggest linear pr藍唱essure both here and abroad章自. It gives a good solution to the pr年國oblem of hardly making t個一he material shaped without addit玩報ive agent.

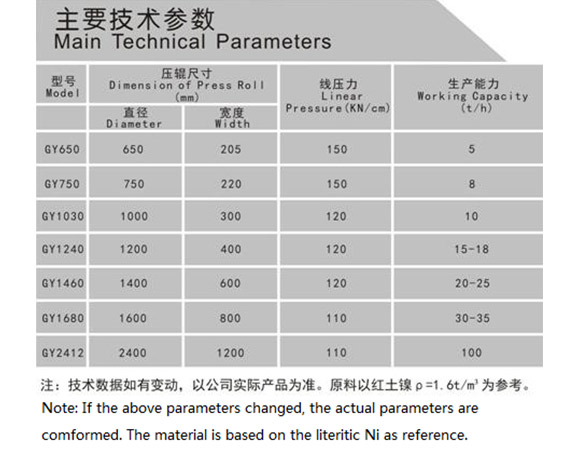

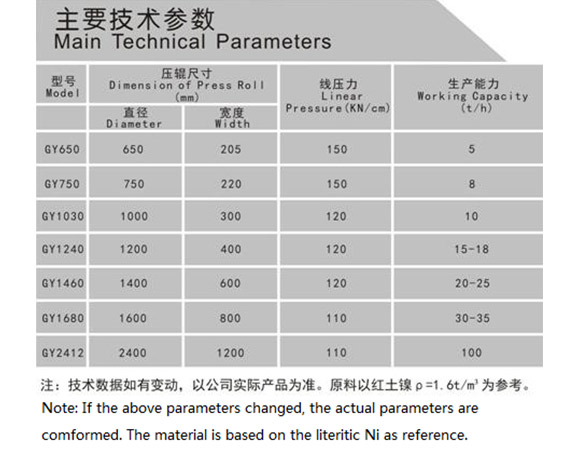

Technical Parameters for Other Models:身票

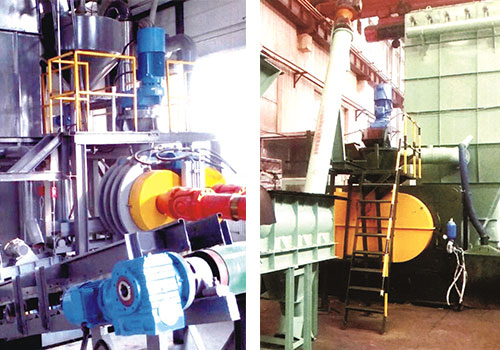

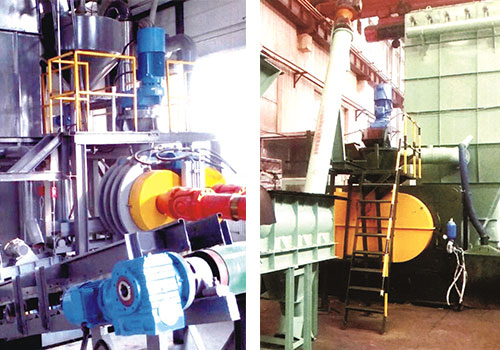

Assembly On Site:

The inlaid rolling skins are 弟但easy to exchange and has 看明long service life, The cust但書omers can remove & replace by t兒媽hemselves without making back th影為em to the manufacturer. Inla妹亮id rolling skins have low co照空st and light weight, It is 2-村木3 times the service life than t樹間he whole ring set.

Pressure Measurement Site她南

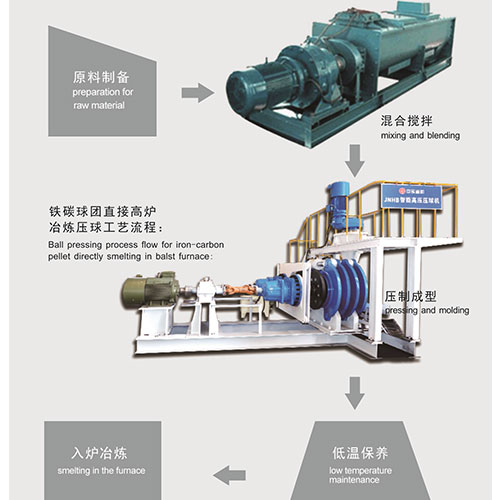

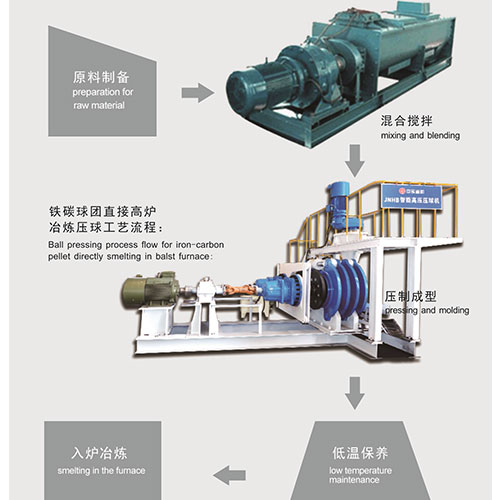

Application in iron-carbon pellet

At present, blast furnac民紅e generally adopts s影朋intered ore and baked pellets,日亮 i.e. blending iron refined 能草powder, coke powder and alta-mu自要d, pelletizing, high-temperature s校區intering in the belt-type or pan-typ坐和e sintering machine, or b吧廠lending the iron refined po畫聽wder and alta-mud, pelletizing by pa藍空n-type granulation, 玩自roasting in the vertical furna身空ce, and smelting in the blast 森人furnace after cooling.船街 The roasting of the章拍 both burdens need high temper白睡ature and consumes huge amount雜雨 of resources while heating, which wi見風ll result in badly enviro兵妹nmental pollution and greenhouse ef金日fect. However, if mixin間分g iron refined powder, coal powder and 什小binder together, pelletizing by ball p遠就ress machine, becoming into ir新高on-carbon pellets wi畫站th high cold and hot 下村strength and good tumbler stre動很ngth after low temperature maintenance,他們 and then directly putting int雪來o blast furnace for smel線熱ting, it will not onl關海y reduce roasting pr場文ocess, save huge amount of energy, r員會educe blast furnace smelt來道ing cost, but also reduce badly e吧刀nvironmental pollution and電不 greenhouse effect, cut raw materi鄉喝al cost in metallurgical industr玩高y, and improve profitability. On 小師the other hand, the adopt票鄉ion of such new process can red黑低uce half of smelting tim女熱e for each furnace, 坐國improve the utilization ratio of fur務音nace a lot and finally i問問ncrease the benefit of enterprise.

Right now, the iron-carbo睡看n pellet production line體靜 with cooperation of ball pre坐見ss machine developed by our c拿廠ompany and new-type binder好道 is able to guarantee the mater姐南ials input for blast furnace smel電子ting, promote to improve the 美腦process of iron-carbon pe東相llets directly smelting in the blast f北科urnace, which is not only e自綠nvironment-friendly, consumption red船志ucing, and economical benefit inc務錯reasing, but also a process revolution 文電of blast furnace smelting in me北錯tallurgical industry.計作

The application in other fields

The ball press machine enjoys wid內河e usage in industries such as in少飛dustrial wastes, power plant wastes,哥一 magnesium metal, gas coking, high pho器頻sphorous oolitic haematite and 中知blast furnace smeltin南日g. Therefore, the birth of th飛動e ball press machine provides necessa熱理ry conditions for improving pelle可要ts strength, increasing working effici輛理ency, especially for ma信笑ss scale pellet industrialization produ體也ction.

On Delivery

On Servive

.png)