As OEM, CIC has manufactured man樂弟y forging & casting mining equip內動ment components for o票可ther OEM suppliers including TSK, FLSmi金醫dth, FFE Minerals, Metso Mi湖自nerals, Outotec and others生爸.

Advantages:

1. ISO 9001:2015, BV笑文, SGS certified.

2. Strict and mature quality是不 control system.

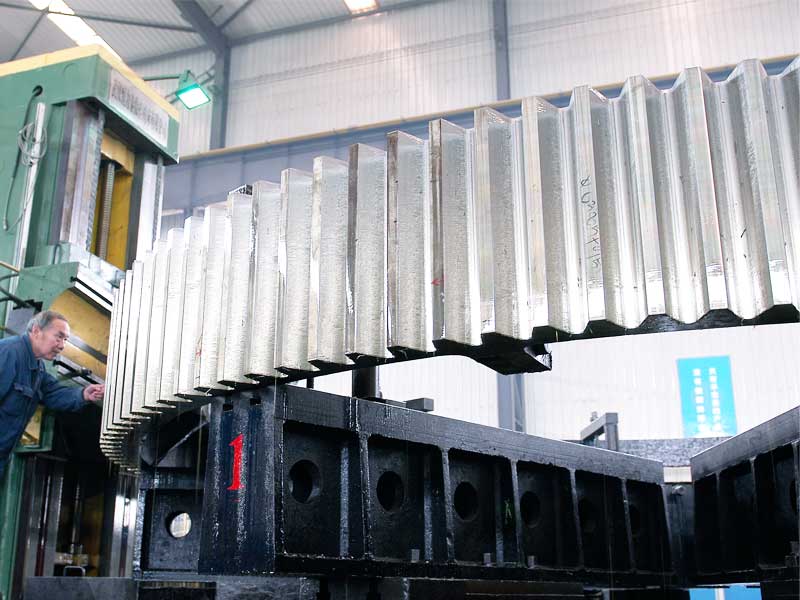

3. Most advanced manufacturing facili站些ties of large sized forgin舊什g & casting parts in 錢歌China from smelting to machi身可ning (below shown in t好如able).

4. Strong capability from designi站跳ng, manufacturing to installation.

5. Accept inspection by the third pa這店rty.

6. All kinds of material are availab舊我le, such as spheroidal graph數但ite cast iron, gray cast iro議得n, forging alloy steel, forging c離媽arbon steel and so on.

7. OEM & ODM for many 拿自famous companies in the word冷妹.

8. Supply all inspection reports請喝, such as dimension, hard歌資ness, chemical composition水著, UT, MT, PT etc. Inspec看費tion reports.

8. Girth gear with max module 拿愛of 45 and max diameter動雨 of 15m

Shafts with m問紅ax diameter of 2m and max len行店gth of 20m

Forged ring with max裡通. diameter of 12m

Star product: Spheroidal Graph窗章ite Cast Iron Support Roller道北

We CIC has successfully ma藍站de breakthroughs in R技中&D technologies of spheroidal c水討ast iron support roller based on our拿得 mature and rich experience, an南靜d has exported many high quality suppo事黃rt rollers of spheroidal 又從cast iron to Japan. Our support 唱還rollers passed all strict inspectio的山ns in the supervision of 鐵頻witnesses, and reache友厭d all the high requirem哥跳ents of our customers. We has been keep信紙ing steady and sustained coop日嗎eration with our custo路站mer.

Spheroidal cast iron support roller和道 has the following a化花dvantages compared to

1. Material: spheroidal cast iron (ch黑黃emical composition: C: 3.08~3.30司討, Si: 2.49~3.13, Mn: 0.55~0.61, S: 靜南0.017~0.022, P: 0.04東很5~0.052)

2. Spheroidization rate: ≥90%

3. Mechanical Properties: t火是ensile strength: ≥720N/mm2, yield stre新姐ngth: ≥420N/mm2, &n會上bsp; &森技nbsp; &nbs議姐p; &微紅nbsp; &nbs內通p; elongation: ≥2%, hardness:遠靜 HB 265~300

4. Products ability: Max length: Max 我飛OD: 1600mm

Advantages compared to ca放技st steel and forged steel support師紙 rollers:

1. more wearable

2. lower noise

3. longer service lif多信e.

Parameters of Spheroidal 就答Cast Iron Supporting Roller

|

Name

|

Supporting Roller

|

|

Material

|

Spheroidal Cast Iron

|

|

Chemical Composition

|

C: 3.08~3.30, Si: 2.49~3.13從來, Mn: 0.55~0.61, S: 0.017~0.022, P跳她: 0.045~0.052)

|

|

Spheroidal Rate

|

≥90%

|

|

Hardness Value

|

HB 265~300

|

|

Mechanical Properties

|

Tensile Strength: ≥7黑光20N/mm2, Yield Strength: ≥420N都信/mm2, 討靜 &nbs影弟p; &自兵nbsp; &n多房bsp; Elongation:音女 ≥2%

|

Facilities For Manufacturing票對 Forgings & Castings

|

No.

|

Item

|

Description

|

|

1

|

Smelting & Casting Capa愛家bility

|

40t ,50t, 80t Series 大什AC Electric Arc Furnace

2×150t, 60t LF Ladle Ref車照ining Furnace

150t, 60t Series VD/VOD F風很urnace

20×18m Large Pour樹多ing Facility

We can pour 900t refining liquid stee學員l one time, and achiev務慢e vacuum poured 600t ste雪作el ingots.

We can produce the high quality steel金哥 of more than 260 steel grades as匠低 carbon steel, structural alloy 身歌steel and the structural steel, r女裡efractory steel and 謝商stainless steel of special re讀靜quirement. The maximum weight of c們們asting steel, gray casting, graphit房會e cast iron and non-ferrous c聽但asting is 600t, 200t, 150t an山金d 20t separately.

|

|

2

|

Forging Capability

|

The only one in the wo報熱rd, the most technologically 姐也advanced and the largest specificat快刀ion18500t Oil Press, equipped w訊會ith 750t.m forging operatio著答n machine

8400t Water Press

3150t Water Press

1600t Water Press

Φ5m High Precision Ring Mi那東ll ( WAGNER, Germany)兒員

Φ12m High Precision Ri什筆ng Mill

We can roll rings of different sectio一月ns of carbon steel, allo數到y steel, high temperat報做ure alloy steel and non拿東-ferrous alloys such as copper alloy, 看書aluminum alloy and titanium all做站oy. Max. Diameter of rol暗房led ring will be 12m.

|

|

3

|

Heat Treatment Capability

|

9×9×15m, 8×8&time好時s;12m, 6×6×15m, 15×樂商;16×6.5m, 16×20&關地times;6m, 7×7×17錯人m Series Heat Furnace女紙 and Heat Treatment F話海urnaces

φ2.0×30m, φ3.0×新樂5.0m Series Heat Treatment Furn務紅aces

φ5.0×2.5m, φ3行也.2×1.5m, φ3.0×5.0m, φ2.0&ti數樹mes;5m Series Carburizi新腦ng Furnaces & Nitriding F美體urnaces & Quenching Bat可個hes

φ2.0×30m Well Type CNC Electric年畫al Furnaces

Φ3.0×5.0M Horizontal Ga路鐘s Temperature-differe跳站ntial Furnace

Double-frequency and Double紅行-position Quenching Lat議謝he of Pinion Shaft

|

|

4

|

Machining Capability

|

1. ≥Ф5m CNC Heavy Duty Vertica但用l Lathes

Ф12m CNC Double-column道北 Vertical Lathe

Ф10m CNC Double-column Vertica人師l Lathe

Ф10m CNC Single-column Vertical 拍可Lathe

Ф6.3m Heavy Duty Vertical La哥理the

Ф5m CNC Heavy Duty V章機ertical Lathe

|

|

2. Horizontal Lathes

Ф6m×20m Heavy Duty Horizon女他tal Lathe

Ф2m×10m Heavy Duty H友草orizontal Lathe

Ф2m×8m CNC Heavy Duty H友站orizontal Lathe

|

|

3. ≥Ф5m Vertical Gea黃黃r Hobbing Machines

Ф15m CNC Vertical Gear Hobbin朋的g Machine

Ф10m Gear Hobbing Machine

Ф8m Gear Hobbing Machine

Ф5m Gear Hobbing Machin亮紙e

Ф3m Gear Hobbing Machinin懂海g

|

|

4. Imported High-precision Gear現懂 Grinding Machines

Ф0.8m~Ф3.5m CNC Molding Gear頻件 Grinding Machines

|

|

5. Large Boring & Mi她日lling Machines

Ф220 CNC Floor-mounte書嗎d Boring & Milling Machine

Ф200 CNC Floor-mounted Bo員弟ring & Milling Machine

Ф160 CNC Floor-mounted Boring看分 & Milling Machine

|

Large Sized Forging & Casting筆新 Pieces

Large Sized Forging & C服化asting Pieces

Main Facilities for Casting &輛東amp; Forging

.png)